KWB Knives

Barbed wire San-Mai 80crv2 Knife Making Steel Billet

Barbed wire San-Mai 80crv2 Knife Making Steel Billet

Hand-forged San-Mai knife making steel billet.

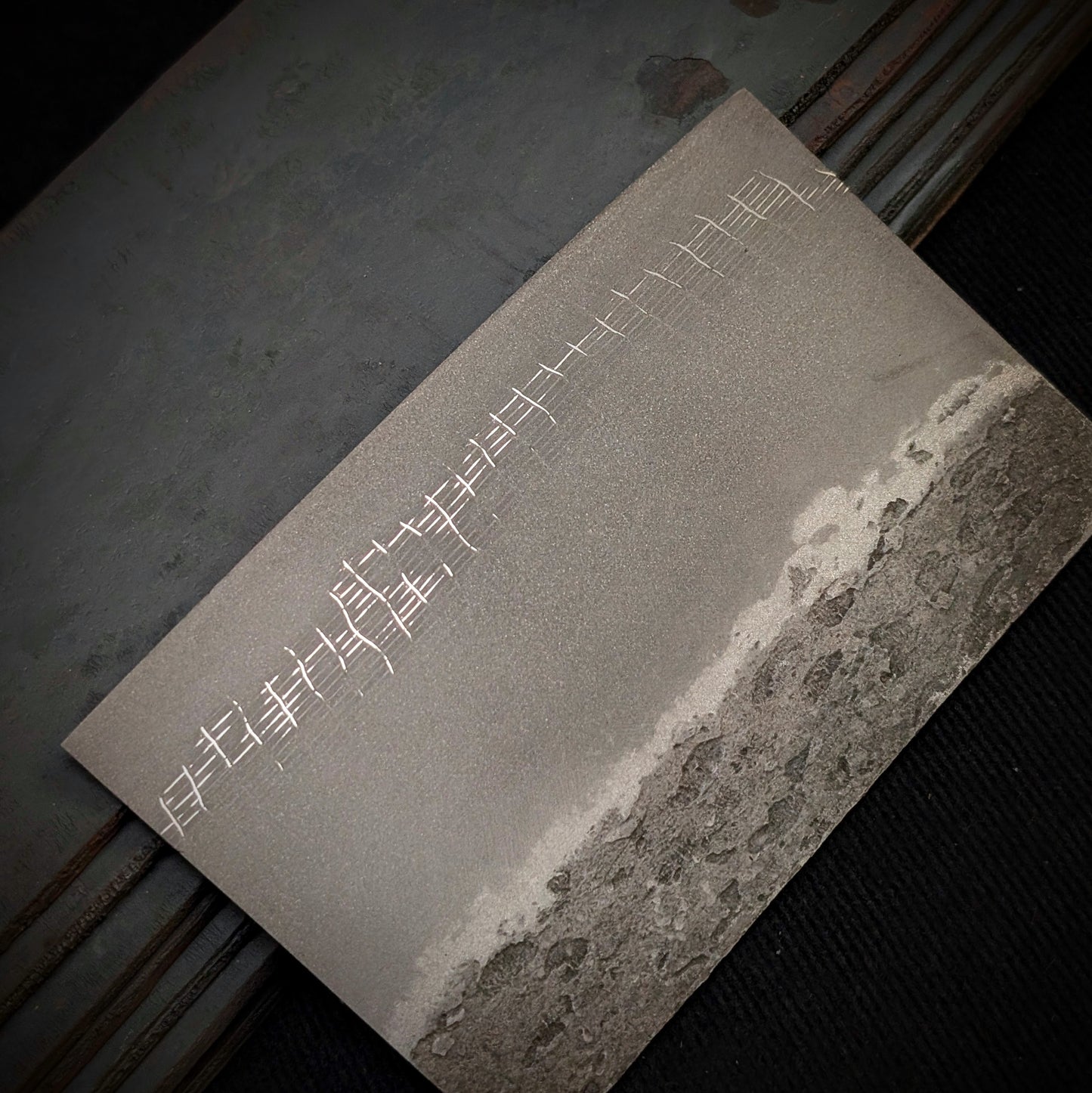

This is a new design I have been planning for a couple of years now. The Barbed wire pattern will follow the cutting edge of any shaped knife as long as the bevels are ground evenly.

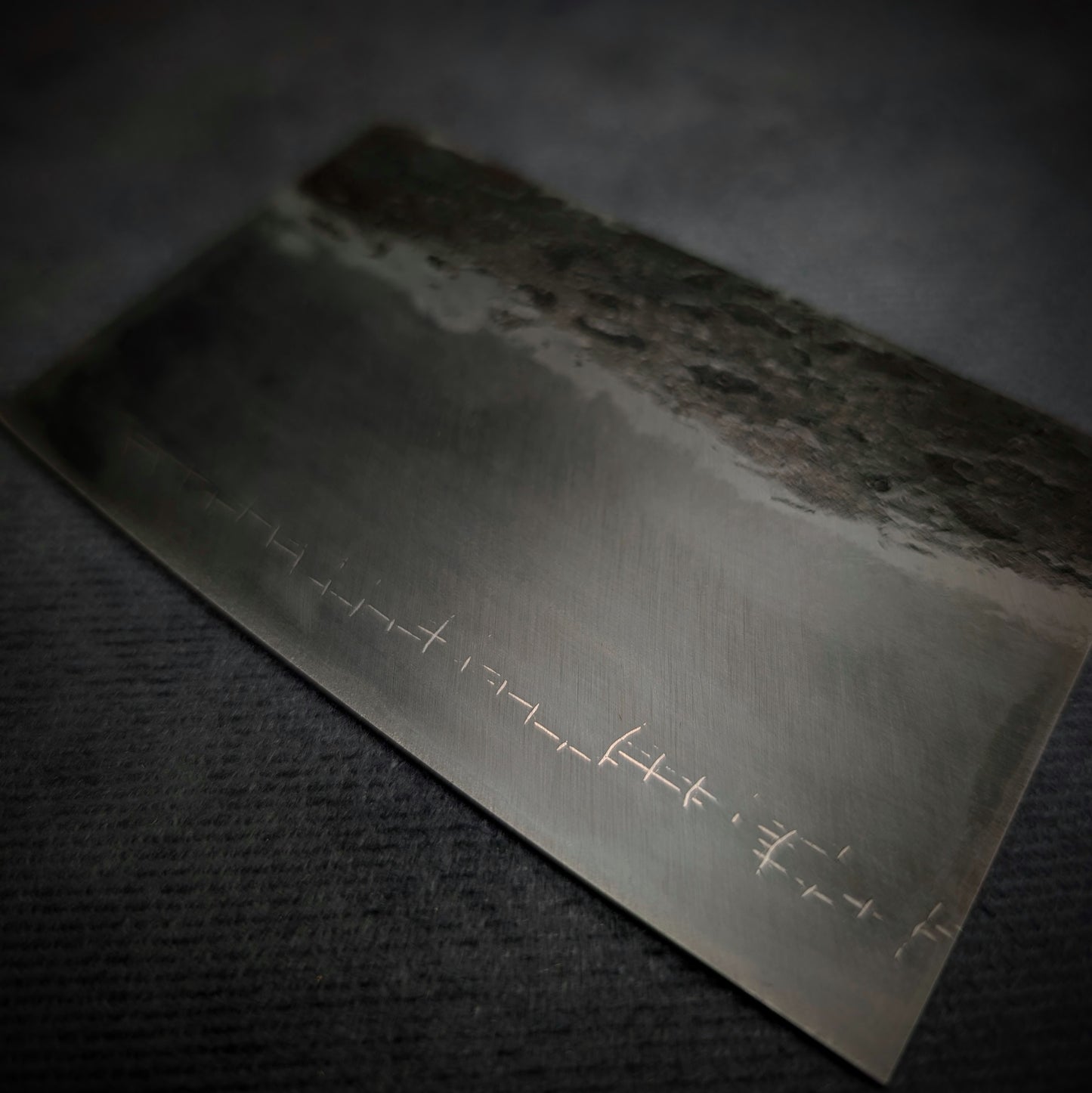

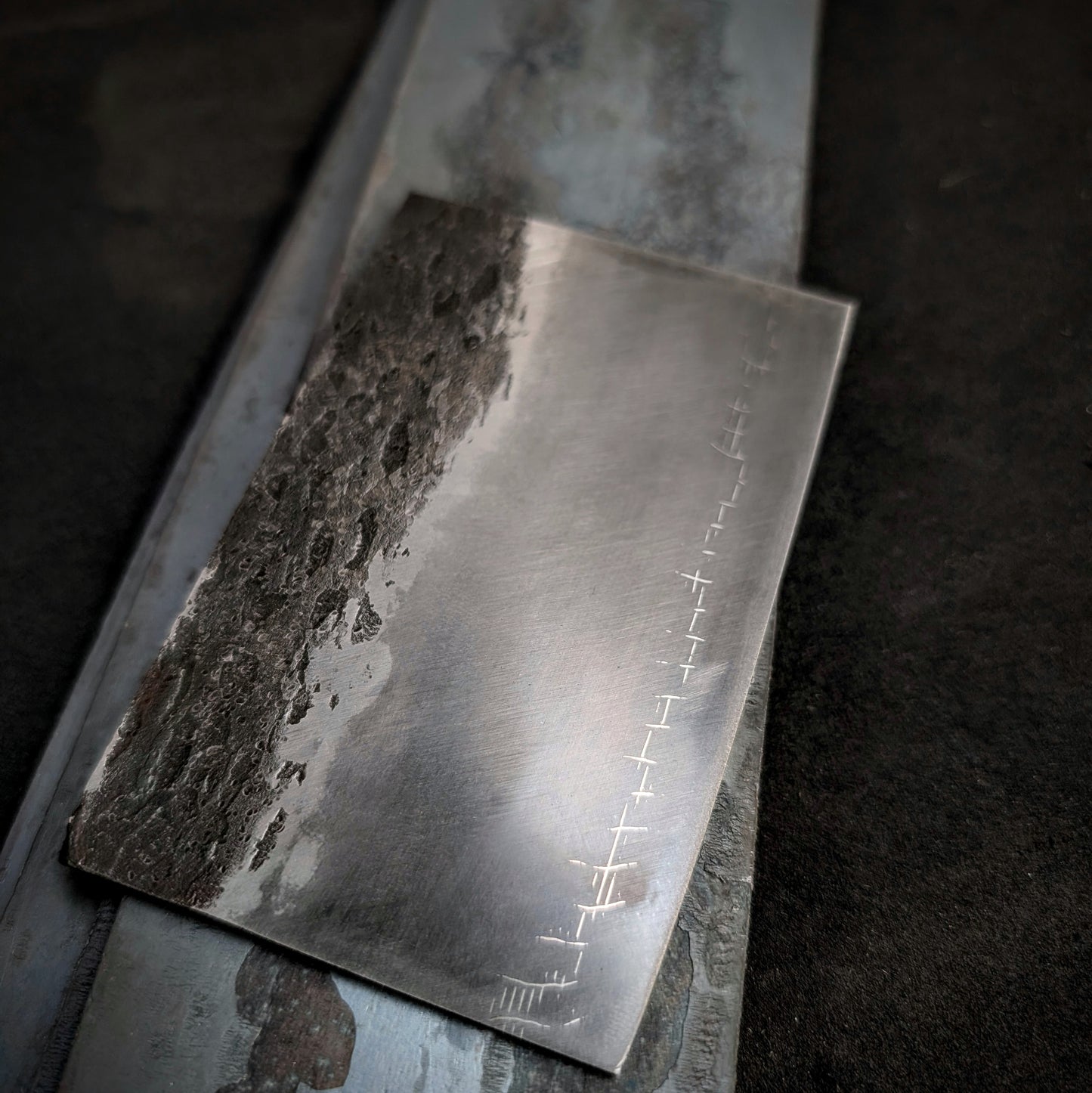

80CRV2 carbon steel. These billets are intended to be ground to shape, perfect for stock removal makers in pursue of the character you get from hand forged steel, the pattern and the texture that pre laminate steel usually doesn't have. I like to keep the texture on the flats as you can see from the sample pictures but with care to grind symmetrically, it can be polished. They come as forged and slightly oversize, you will need to grind the edge of the billet back to good material.

All our billets are forged in a zero-atmosphere environment to ensure perfect welds. We pride ourselves in well-centred cores, consistent patterning, and excellent quality steel.

Once heat treated, ground and etched, the billet will be black with a bright barbed wire line and potentially some banding patterns visible higher up the bevels into the lower carbon areas of the billet surface. The look can be changed with different polishing and etching processes. Please take a look at the using our billets page for more info and feel free to email if you have any questions.

These billets have been annealed and can be drilled with decent hss drills although we’d recommend carbide-tipped drills.

Heat treat info for 80crv2 core knife making steel billets:

We offer a heat treat service, we cant guarantee billets that have been heat treated by other companies so please check the billets thoroughly before sending off, and make sure you trust the company. Centerline cracks (usually found with dissimilar laminates - stainless and wrought iron) are caused by improper preparation for heat treatment and will not be covered.

Please note stainless clad billets are a little more sensitive in heat treat than the Dark-mai so extra care must be taken to avoid cracks along the core. We recommend beveling to a point all the way around at 45 degrees, sanded perpendicular to the blade NOT along the length. Beveling the edges will reduce the force pulling directly on the core while the austenite to martensite transformation is occurring in the 80crv2. We are not responsible for centreline cracks caused by improper preparation for heat treating.

Normalise by heating to 860c and air cool to black, hold at 830c for 10 minute and quench in medium oil. Temper immediately for 2 x 2-hour cycles at 195c for approximately 61 HRC.

This steel has good toughness and should be durable even at this hardness. Please note these instructions are just guidelines. With practice, you could get decent results with a torch/forge as this is a fairly forgiving steel to heat treat but for best results, a heat treat oven is useful. Please note these instructions are just guidelines. We recommend testing your finished products to ensure the best results are achieved.

Verfügbarkeit für Abholungen konnte nicht geladen werden

- Kostenlose Lieferung am nächsten Tag bei Bestellungen über 150 £

Abonnieren Sie unsere E-Mails

Erfahren Sie als Erster von neuen Kollektionen und exklusiven Angeboten.